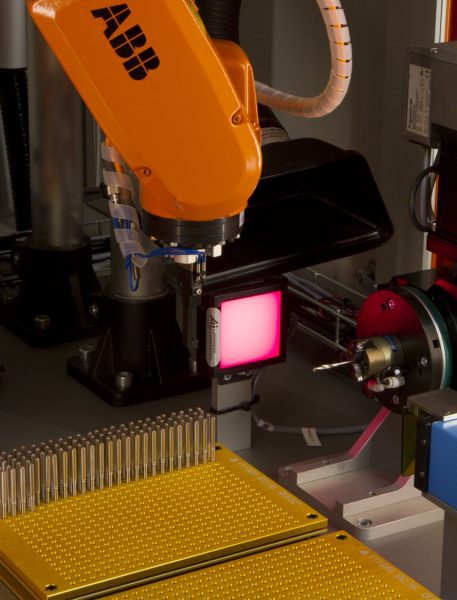

Advanced production equipment and automation

At pace with new breakthroughs, we have invested increasingly in advanced production equipment, manufacturing techniques, and automation to improve quality, cost-effectiveness, and delivery reliability. All manufacturing at Elos Medtech is hallmarked by the highest quality combined with flexibility. Advanced measurement equipment is used both in serial production and during final inspections. Production quality is assured across many steps through statistical process management or AQL sampling.

Increasing production efficiency

Our focus is to constantly increase the production effectiveness, by increasing automation and the installation of robots as well as setting up production cells. We have implemented electronic measurement value management, where we double-check all critical measurements. This has resulted in our ultramodern machine park with both optical and detecting measuring machines of the highest quality.

Metal machining, turning, milling and welding

We have extensive experience in turning, milling, and welding of titanium, high strength stainless steel, brass, and chrome cobalt used in medicine and biotechnology. We have extensive experience in milling and welding of ceramics, such as zirconium dioxide and PEEK. We continuously invest in even more advanced production equipment while remaining cost-effective.

Do you want to focus on your core business?

State-of-the-art manufacturing technology, deep expertise, and high quality standards. This is what makes us a trusted partner to the medical device industry.