More OEMs are looking for CDMOs that prioritize sustainability. Elos Medtech continuously makes strategic decisions to make our development and manufacturing of medical devices more sustainable. One of them is the investment in a machine that allows us to reuse cutting oil. The result? Less consumption and less waste, which mean less environmental impact.

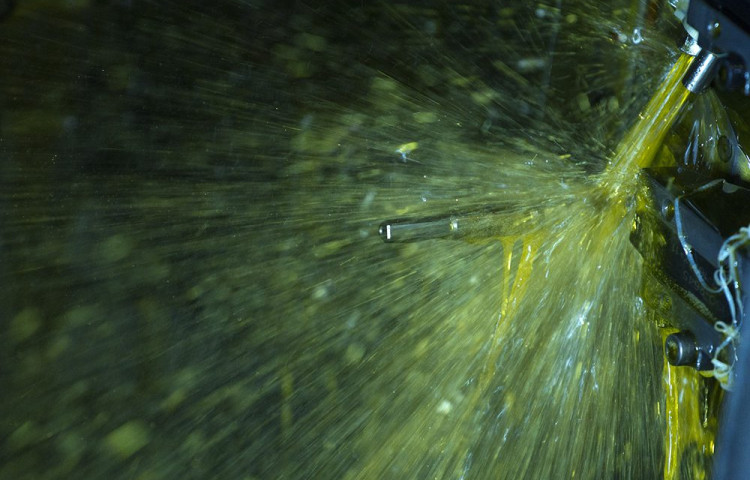

A machine that filters and recycles cutting oil

As part of our sustainability strategy and to minimize our climate footprint, we continuously replace old equipment with new, more sustainable machinery and technology. Last year, our production plant in Denmark initiated a project with the ambition to reduce the consumption of cutting oil. And so, we installed a new machine that filters and recycles it.

What is cutting oil?

Cutting oil is specially designed for metalworking processes. It is used during the machining of metals to provide lubrication and cooling. The lubricant helps improve machine performance, prolong the life span of cutting tools, and prevent rust on workpieces. The cooling keeps the workpieces at a stable temperature, which is critical when working with products with fine tolerances, such as dental implant components.

Manufacturing of dental implant components

In our production site in Denmark, our key focus is developing and manufacturing dental implant components, instruments, and tools for digital workflows as well as standard prosthetic solutions. We also serve the medtech market in the fields of orthopedics, diagnostics, and hearing devices.

CNC turning whittles down materials to sheer perfection

When working with the fine tolerances of dental implant components made from titanium, stainless steel, and medical-grade plastic, the technology of CNC machinery is required to whittle down these materials to sheer perfection.

During CNC-turning, we use cutting oil to improve machining properties and ensure a consistently high quality of our dental products – whether being products we produce for our customers or our own Elos Accurate® product portfolio.

Reusing cutting oil – minimizing chemical waste

When the CNC-turning is done, the used cutting oil must be disposed of as chemical waste. But with our new machine, the cutting oil from the machining process is instead filtered and recycled. The oil is taken out from the machine with the swarf on a conveyor, removed from the swarf in a centrifuge, and then filtered in the mechanical filtration system. This reduces the need for new cutting oil.

Medical device manufacturing made sustainable

As we use oil for all our metalworking processes, we normally consume a lot – about 10.000 liters per year in Denmark alone. But with our new machine, we can reuse nearly all of it. This means less consumption, less waste, and less environmental impact. In fact, we have already reduced our purchase of new cutting oil by 70%.

Our new initiative also aligns with the UN’s global goal 13 to combat climate change and its impacts. We are confident that making strategic investments with sustainability in mind will not only reduce the environmental impact of our business and make medical device manufacturing more sustainable – it will also contribute to protecting our planet and ultimately improve the quality of life for people.

Are you also looking for a CDMO that prioritizes sustainability? Find out what else we do to take economic, social, and environmental responsibility for our business.